Starting in March of 2015, we tried to troubleshoot our

Airstream Interstate's original

Dometic 2351 3-way absorption refrigerator, and you can read about those misadventures

here.

Upon conceding failure with that troubleshooting, we replaced that Dometic 2351 with a new Dometic 2351 and you can read about those additional adventures

here.

Twenty months after we installed the new Dometic 2351, it

again went on the fritz.

|

| The Dometic 2351 does not come with a built-in thermometer, so we made one, just as we had with the first unit. For that reason, we knew immediately when something went wrong. Internal temperatures were sustaining in the 44 - 55 degree range even when the outside temps didn't rise above the 80's, which of course is unacceptable. To be absolutely certain of what we were seeing, we also used a conventional thermometer to take its temperature, and the two agreed very well. |

|

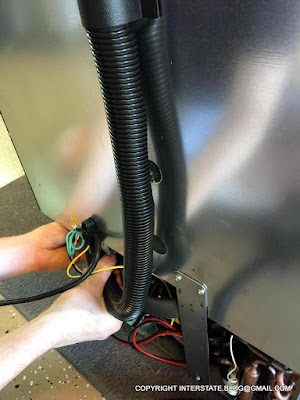

| We followed procedures specified in Dometic's own Diagnostic Service Manual (PDF) to try to diagnose this second break-down. That included bypassing the thermostat in two different ways (my husband's DIY hot-wired resistors are visible near photo center above) to cause the fridge to run "full blast", to see if it would get colder. Which it did not. |

Somebody shoot me. I'd like to say that

I can't believe we wasted our money on a second fridge of the same type, but unfortunately I have to believe that. Back when we made that decision, we had only one Lifeline battery - not the lithium set-up we have right now, which gives us approximately

five times the usable power compared to our OEM set-up. So back then, we had no choice but to buy another 3-way absorption refrigerator and obviously we did not choose well.

Why did our second Dometic fail? An ominous quote from the Diagnostic Service Manual reads,

“A refer (sic) that chases the out-side (sic) temperature is improperly vented or has a weak cooling unit.” (page 24). We were seeing the temperature chase ambient, but we knew that there was nothing wrong with our venting. So how could the cooling unit have suddenly become "weak"? There are various speculations on the internet, including an intriguing possibility expressed in

this forum thread, which is that one of the gas components, namely hydrogen, leaks out preferentially from the welds in the cooling unit, given that it's THE smallest molecule in existence.

|

| Ya don't say. Not very good news for absorption fridge owners, obviously. |

Once hydrogen escapes, the unit doesn't perform as well, and there you have it. "Weak". Or so the theory says.

To make a long story short, I researched the available replacement possibilities in the realm of two-way rather than three-way fridges. A well-known RV upfitter had recommended that I consider either the marine fridges of brand name Vitrifrigo or

Isotherm, so those are the ones I stuck to. Rumor has it that

Norcold is experiencing major failure rates right now (one source claiming 80% returns!!! Plus

they had major recalls even before these latest reported problems, so I did not even consider that brand.)

|

| Here's a screenshot of my comparison spreadsheet. |

As you can surmise from the chart above,

Vitrifrigo would have sold me on the size of the freezer alone, but it was also well-regarded by wholesalers in my location, which contains one of the largest boating communities in the world.

I had a lot of trouble verifying the specs of these fridges, though. Dimensional information on the internet was limited and often contradictory. Customer service was no help. Vitrifrigo itself is an Italian company which appears to have very poor representation here in America. No retailer carried either of the models I was evaluating, so I could not view them in a brick-and-mortar to confirm that internet thumbnails were showing the actual product I was looking for.

|

| Experiences like this were common. Do you ever visit a webpage and have these annoying "Can I help you?" pop-ups appear only to discover that there's nobody on the other end? It's just a useless bot. |

Fortunately I found a really good wholesaler who was willing to crack open one of his shipping boxes so that I could examine the

Vitrifrigo C115IDB4-F in person, in his warehouse.

|

| If anyone needs to know where and how to buy marine parts in the greater Houston area, email me. Sometimes I don't list vendor names because of "law of unintended consequences" type outcomes. But I'd be glad to share stories. |

That model link I gave above is to a UK site because I can't find a decent American sales listing as I'm writing this... case in point regarding the difficulty of finding information.

|

| This is generally regarded as a fairly knowledgeable source, IF their site happens to be up and running while you are searching. |

Having been satisfied with what I saw in the warehouse, I phoned one of my favorite marine parts retailers and had them issue a purchase order to the wholesaler. Then I happily carried this baby out of the wholesaler's establishment, stopping in at the retailer to sign my credit card receipt on the way home.

|

| Literally. It came home in our Interstate, which I was using as my daily driver until we got this refrigerator issue under control. Here you can see the original cabinet opening where the cursed Dometic had been removed. |

Here's how this Vitrifrigo compares to our useless Dometic 2351.

|

| The Vitrifrigo is visibly better construction quality. There's a temperature control knob (black circle at lower right), and it has a light, neither of which the Dometic has. It's also a slightly larger cubic foot size, I think... I could not locate any published statement as to the Dometic's precise volume. |

|

| Even if we could get a Dometic 2351 that didn't break on us, this right here would make the slightly higher price of the Vitrifrigo worth it. An extra 5 inches might not seem like a lot, but in a camper van, every inch counts, and having a larger freezer is HUGE. |

The Vitrifrigo's cut-out size, and especially it's face mount, was larger than the Dometic, which required us to do cabinet surgery. Everyone's cabinetry will likely be somewhat different, so I won't run through this procedure step-by-step. I'll just show some general provisions to give you an idea how we accomplished this. In our case, it proved to be quite time-consuming.

I'll talk about adjusting the width first, then the cabinet height. But because this became an iterative process for us, with a couple of mid-project do-overs, some of the photos below do not show full continuity.

|

| Remember, our space was designed for a 3-way fridge, and a 3-way fridge produces a potential combustion gas penetration hazard (think carbon monoxide). It took me about 2 hours just to get a portion of the caulk off the inside of the cut-out. And while I was engaged in this caulk-stripping, I also ripped up the frontal portion of the sheet metal that had been poorly installed. I discovered some minor water damage in one corner, probably from condensation dripping out of the fridge after it had been turned off and left open to dry (we always tried to control condensation by applying absorbent rags, but it didn't always work perfectly). I sealed that area up later in this process. |

|

| The first task was caulk removal. The second task was to remove face trim pieces one at a time. |

|

| These things were glued, screwed, caulked, stapled, taped, and doweled. Literally, all six of those attachment methods were used in this cabinetry process. This was not pre-fab cabinetry and, complicating the removal, the face frame had been built partly in Airstream's shop, and partly in-situ. In other words, there was no consistency from place to place. |

We needed to expand the width of the opening to about 23 inches (including frame overlap) to accommodate the Vitrifrigo (the inset number was smaller than this).

|

| That meant deleting all of the trim on the right side, where it was deeper and more layered. |

Here you can see how that right side was constructed:

|

| Obviously they trenched and sunk those screws before attaching the right section to the left section... what a hassle, because it meant we could not peel it back layer by later. We had to remove this entire compound piece and then break it down, rather than leaving the section we needed in place. |

Here below you can see the right side with that entire strip removed.

|

| You can see the caulk smear and the notch in the base plate where it had fit. The compound piece itself is visible at photo lower right. |

As I started to say above, I tore off the sheet metal liner on the front portion of this space because its caulk job was irregular and un-salvageable. But that left the original raw plywood exposed, so I sealed it by adding three coats of oil-based enamel, the same enamel paint that I'd used on the lithium chamber ventilation screen that you can see at photo left above. Even if nothing in the fridge leaks or spills

per se, drips of condensation can still make their way out the door and down onto its support platform. That's what had caused the discoloration that was evident on the raw plywood. The original metal sheeting here was not installed in a waterproof manner.

Or, even if drips don't occur, wood should never be left raw in a camper van, especially in our subtropical climate. That's just asking for trouble.

|

This photo also shows the painted plywood, and also shows that there was only one inch of original face trim on the left side of the cabinet to begin with. It was the right side that had been built out several inches. You can see the corresponding notch in the bottom shelf toward photo bottom, where the compound piece had been removed.

I left the sheet metal lining intact in the rear of this chamber, because it was in good shape in that location. |

|

| We decided to do the extra work to achieve an inset of the refrigerator, which meant cutting the original vertical trim piece off at the height of the shelf, removing the upper leg entirely (this pic shows part of that upper portion still in place, before we figured out that it had to go). Every inch counts in an Interstate, and having the fridge slightly recessed would help prevent it getting bumped, the handle getting snagged, etc. But given that we'd adjusted the width, there was now a hole at the bottom where the trim had previously extended straight up. The most efficient way to finish that out was the create a threshold out of quarter-inch plywood, much like the threshold for a door. |

By the way, before I forget, here are the details on the gray paint I used throughout this project.

|

| Sherwin Williams "Iron Ore". Note that it's an oil-based enamel. |

|

| It's a pretty good match to the existing countertops. |

We originally thought that we could salvage some of the original face trim, but that proved not to be the case because Airstream's OEM DC wire bundle plus the solar wiring were interfering with the refrigerator on the rear left side. Therefore we had to remove all the original face trim, and basically start over, in the most minimalist way achievable.

|

| We had to cut that right trim flush... and of course I sealed the raw plywood edges with oil-based enamel... |

|

| ...and then we added an entirely new bottom plate, and a down-rod at left (solid oak). |

You'll notice the left down-rod has a gap between itself and the left wall of the cabinet. My Class B mantra: Not a single inch wasted.

|

| If we were forced to push the fridge all the way to the right to avoid the wire bundles, so be it. But why waste the resulting space on the left? |

That space is pure gold - a precious 0.7 cubic feet, albeit in a really strange planar configuration. But not strange for a Rumpl blanket. I cut a "spine" for it out of coroplast (plastic cardboard) and used two of my big prepper elastics to cinch the Rumpl to the coroplast, to give it shape and stiffness so that I could slide it in there. Not only does this create blanket storage (ALWAYS a problem in any Class B), it also increases the effective insulation for the fridge. Obviously this view above is with the fridge not yet in place.

|

| There's a view of that offending DC wire bundle (1 of 2) that we had to avoid by pushing all the way to the right. The while line you can see is caulk, and the gray at the base of the DC bundle is some Sikaflex 221 we used to plug this hole. We have electrical workings underneath and to the left of this bundle. |

|

| We also replaced the vinyl flaps that Airstream had installed around the former fridge. But let me not get ahead of myself... |

OK, so, achieving the correct new

width was the relatively easy part. Adjusting the cabinet

height was a female dog.

|

Because you're an Airstream Interstate - THAT'S WHY!!

Jackie Chan, one of my all-time favorites, whose work ethic resonates so deeply with my immigrant heart. |

|

| Difficult because we had to move the microwave shelf up about a half an inch to accommodate the Vitrifrigo mounting frame. But the microwave shelf was not a simple shelf... |

|

...rather, it was structurally integral to the "chimney" that had been built to vent combustion gases from the original 3-way refrigerator (see that area extending upward at photo right). Plus Airstream's vehicle-wide DC wiring bundle ran up through that shelf through a hole, not a notch. And that stuff in the gray conduit is part of the solar wiring.

As it always is when working in the tight space of a van, it wasn't just difficult. IT WAS COMPLICATED, TOO! |

James of

The Fit RV gloats every time a van project demands that he purchase a new woodworking tool. So does my husband.

|

| In this case, it was an oscillating saw, with various blades. The piece of plywood beneath it was used as the spacer. The cylinder in the foreground is the nozzle of the Shop Vac. |

|

| Because of the way this cabinetry was put together, we had to surgically excise a nominal half inch so that we could raise up that microwave shelf enough for the Vitrifrigo face frame to achieve clearance. |

|

| See how that works? Isn't that cool. |

|

| Actually it wasn't cool, at least not literally - it was really friggin' hot. Temperatures in the van climbed above 100 degrees F as we did this job. It was so hot that I could not bear to exert myself to make the usual big step up onto the hitch platform without assistance, so I needed this extra stool for my feeble, overheating self. People sometimes ask me how I find the time to write blog posts. That's easy to answer - I'M IN THE DEEP SOUTH!! I'M DYING HERE!! I have to stop working periodically and sit motionless (all except for nine digits typing furiously) in the air conditioning until I cool off again. |

I'm trying not to complain, but I'm not always succeeding these days. Let me say it again. It was miserably hot from start to finish with this job.

|

| That's one of my favorite emojis. Especially this time of year. |

The fully-excavated shelf area looks like this, and you can see the complexity of the woodwork.

|

| You can also see a bunch of electrical running all through there. The AC plug is for the microwave. Obviously you need to be very careful when cutting in an area like this. And observe electrical lock-out tag-out protocols. |

As a rule, I never leave any raw wood edge exposed in the Interstate. It's just asking for trouble. One spill of liquid or leak of water, and you've got swollen plywood and ruined cabinetry.

|

| This is a small piece of that same plywood that I left out in the rain last week for illustrative purposes. |

There's no need to run that risk. Seal the exposed edges of your plywood - at least it will buy you some time if you have a spill incident. Look for unsealed edges when and where you can. In our rig, Airstream generally did not do this edge-sealing.

|

| In this case, we had insufficient time to allow oil-based enamel to dry as we did with the bottom shelf, so I sealed everything here with gray-tinted water-based Kilz. The one-by-one wooden brackets that you see in this view were waxed, presumably by Airstream, and can't be painted or stained as a result. |

|

| Here's a view of the shelf re-inserted, and the spacer fitted beneath it. Later, those two vertical trim pieces had to be removed (what did I say about photo continuity?). |

|

| Here's the corresponding top view of the microwave shelf, repositioned. The holes in the sides of the shelf are the screw holes for anchoring the microwave. |

As it turns out, the resulting narrowed gap above the microwave was no longer tall enough to store my cutting board because I cannot get my fingers in there. But it did turn out to be perfect for this item which has long eluded effective and protective storage:

|

| My Mapsco Texas Road Atlas. No other map is as thorough and accurate - no paper maps, no GPS database. Only this one will serve for our kinds of backwoods travels. And now it wedges in there tightly enough so that it will not go flying onto the floor when the rig is in motion. |

Every inch of storage counts in a camper van. Every single opportunity for storage must be leveraged. Finding a half-inch space to store an atlas is golden.

Just before we loaded in the fridge, we covered its rear refrigerant line with the same plastic wire conduit we'd used for the interior DC wire bundle. All that refrigerant line had for protection was the usual layer of spongy foam which, in this tight environment, didn't seem sufficient (as evidenced by the fact that we'd already nicked the foam during fridge fitting trials).

And speaking again of space, finding 0.7 planar cubic feet is also golden. At first my husband was not convinced that storing a Rumpl next to the fridge was such a good idea. Then he actually heard the Vitrifrigo compressor with his own ears, the

Danfoss compressor that is widely rumored to be silent.

|

| Silent my sweet buttocks! That's the decibel reading in front of the cabinet slot, without the Rumpl blanket in place. |

Oh, and let me not forget to make this important point.

|

| This is actually a larger fridge than the Dometic 2351, but because we recessed it into the cabinetry, the door doesn't come anywhere near to hitting the opposite cabinetry. This is an issue with some Dometic installations in Airstream Class Bs, as this forum thread attests. |

And now for the money shot...

|

| There she is - Miss Italy this time, rather than Miss America. |

And also the money shot on Danfoss compressor noise attenuation...

|

| Much better. The Rumpl does result in a significant noise reduction. Plus I get the blanket storage. How rad is that, to use #vanlife-speak? |

And the money shot showing that the serendipitous noise attenuator is not impinging upon the coil...

|

| This is the view through the old side vent that the propane fridge had used for air intake. We may devise a small shield to go here, although I think the risk is minimal. I think mostly the blanket is at risk of getting damp from exposure to outside air. |

And the big question - how does this fridge perform?

|

| I left the thermostat in the half-way position overnight, with no load on the fridge, only two water bottles (it's difficult to keep a fridge cold unless there's a load of food in it to "hold the cold"). The freezer portion turns sub-Arctic very quickly. This is what the fridge got down to, with a corresponding lithium battery draw-down of about 11% overnight. It was cycling (and it's a two-stage compressor, I note from the sound of it) but I probably left the thermostat too high for prevailing conditions, especially with no food load. |

We plan to run a bunch more tests today, with the thermostat turned down further, and also we want to track power consumption with respect to the batteries. I'll update this post with any significant findings.

Edit, same-day: The fridge immediately dropped into the 30's when I turned down the thermostat. And this despite the side of the van being too hot to touch with the fingers in our blazing heat.

Second Edit: Here's what our BMS (

Electrodacus) looked like overnight as it was cycling. My husband surmises that the compressor ran about one third of the time. Overnight low temps in our area were probably around 75 degrees (we're located in the subtropics). I think you can see the effect of the "soft start" multi-speed compressor here (all those spikey narrow peaks).

Here is the

Cruisers Forum thread that corresponds to this blog post BTW. And

here is the

Air Forums thread that includes discussion of some of the same content.

|

| I shouldn't complain but I find it hard not to. On the bright side, we need demanding conditions in which to properly test a new refrigerator. Well, we sure as hell have them. |

Thanks. Great info.

ReplyDeleteFantastic detail - I am trying to decide right now between a Vitrifrigo, Isotherm or Novakool to replace a Dometic 2354 in a 2005 Roadtrek 190 - I invested a good 30 minutes with the Vitrifrigo rep over the phone along with sending him all my measurements & he ended up sending me details on 2 of 3 units that would never ever fit - I am a little concerned that the Customer Service might be an issue

ReplyDelete